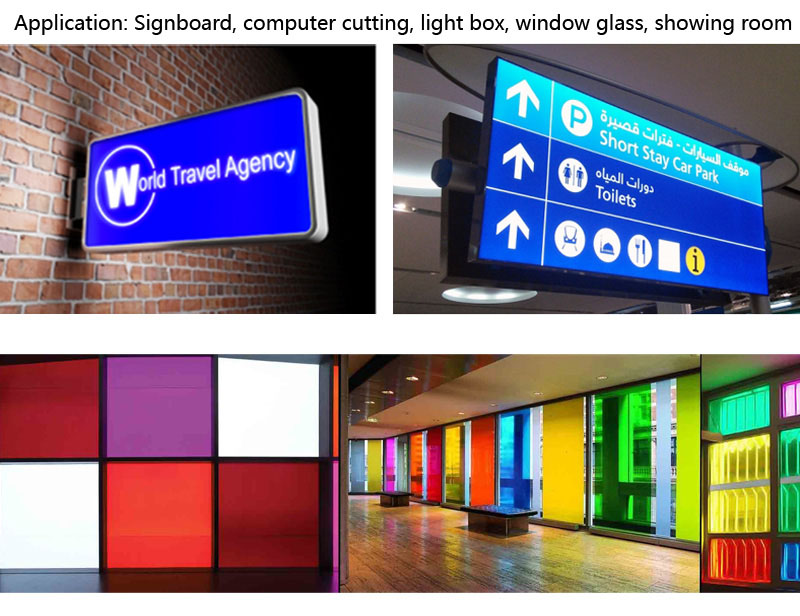

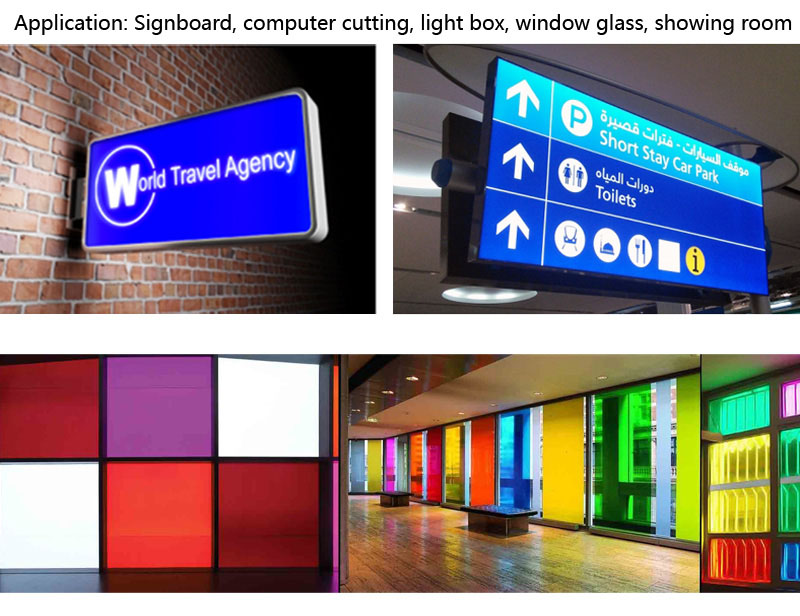

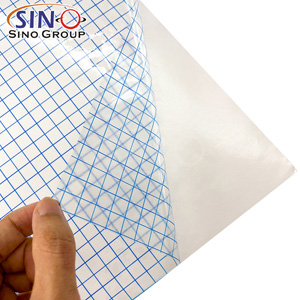

SINOVINYL® Translucent Vinyl is semitransparent, mostly use for signboard, computer cutting, light box, window glass, showing room.

Easy to cut, self-adhesive, and removable, indoor vinyl is the perfect way to add your favorite quotes and designs directly to the walls of your home.

Best of all, this vinyl film removes cleanly and easily for up to 2-3 years after application and has a matte surface that suppresses unwanted reflection. It’s an ideal choice for temporary and short-term indoor graphics.

What is the advantage of SINOVINYL® translucent vinyl?

The SINOVINYL® translucent vinyl with 6 advantages:

1. Removable:

When you stick on the wall, glass or any other smooth surface, you can remove it any time, and without the glue leave on the surface.

2. Friendly materials:

The SINOVINYL® translucent vinyl raw material made by PVC and solvent glue, no smell, no formaldehyde, can be stick in the home room wall or glass.

3. Long durability:

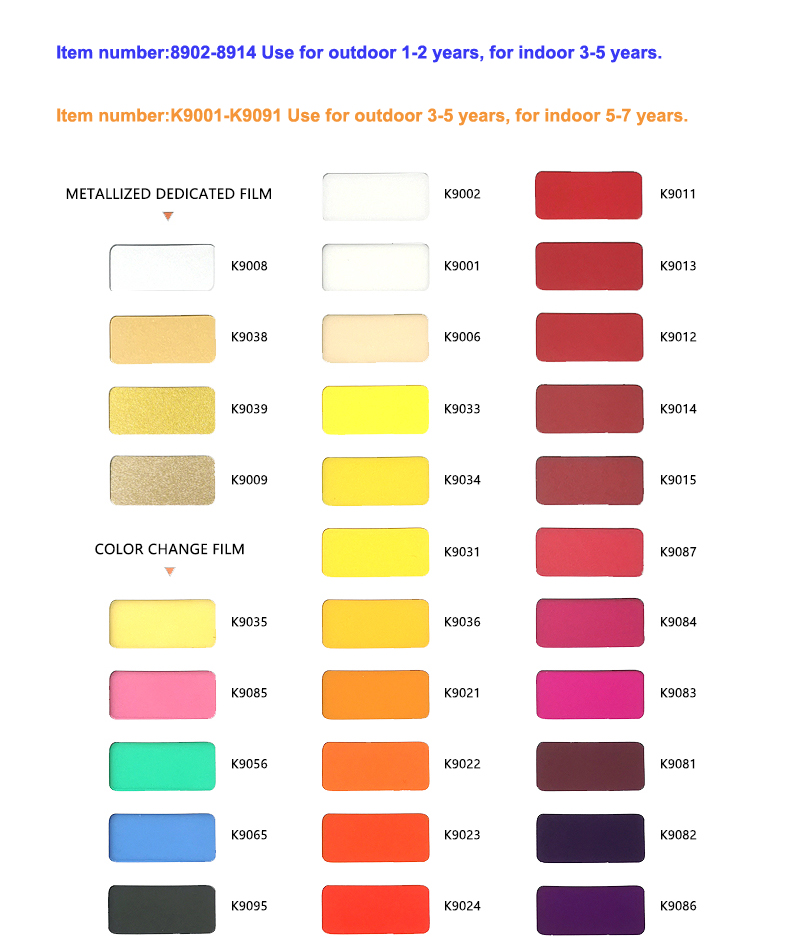

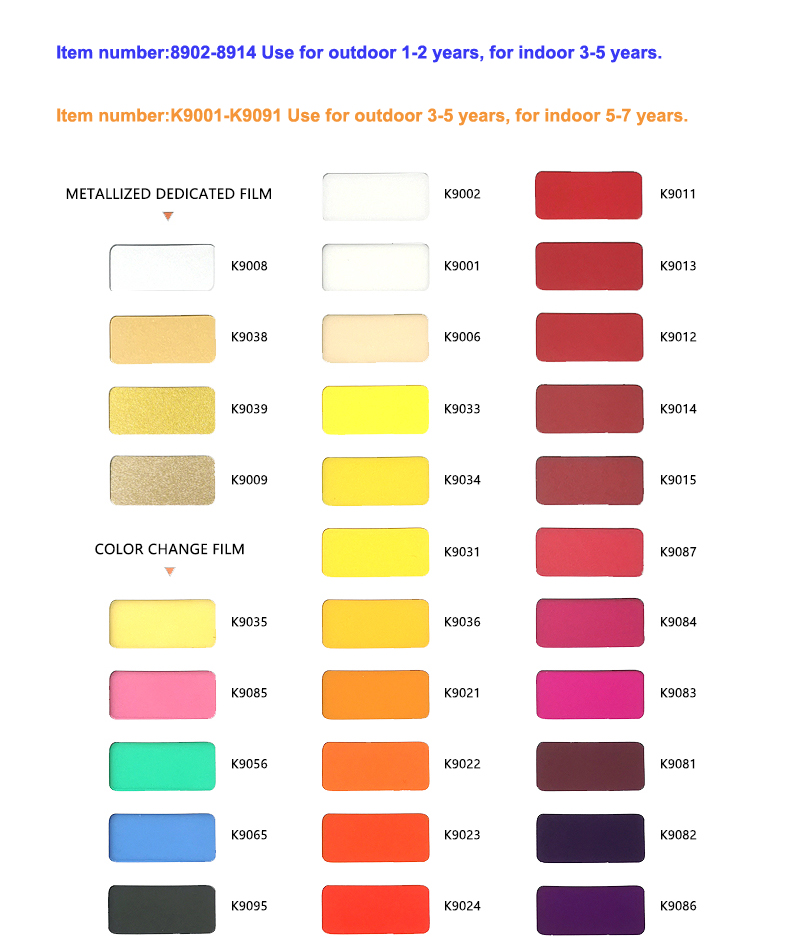

Item number:8902-8914 Use for outdoor 1-2 years, for indoor 3-5 years.

Item number:K9001-K9091 Use for outdoor 3-5 years, for indoor 5-7 years.

4. Easy to application:

SINOVINYL® translucent vinyl is easy for vinyl cutter plotter, easy to cut and application on the wall, glass or any other smooth surface.

5. Multi colors:

With more than 10+ colors, super gloss and super matte surface.

6. Versatile widely use:

SINOVINYL® translucent vinyl can be use for vinyl cutting plotter, letters and patterns cutting, outdoor and indoor graphic poster sign, wall and glass decoration, home decor, furniture, car decal sticker etc.

How to use SINOVINYL® translucent vinyl?

1. Design creation in the computer

Computer designed images are loaded onto the vinyl cutter via cords or over wifi depending on the model. Then the vinyl is loaded into the machine where it is automatically fed through and cut to follow the set design.

2. Use the vinyl cutter to cutting

The vinyl cutter uses a small knife to precisely cut the outline of figures into a sheet or piece of vinyl, but not the release liner. The knife moves side to side and turns, while the vinyl is moved beneath the knife. The results from the cut process is an image cut into the material.

3. Weeding the release paper

The material is then ‘weeded’ where the excess parts of the figures are removed from the release liner. It is possible to remove the positive parts, which would give a negative sticker, or remove the negative parts, giving a positive sticker. Removing the figure would be like removing the positive, giving a negative image of the figures.

4. Use the transfer tape to position and transfer the vinyl

A sheet of transfer tape with an adhesive backing is laid on the weeded vinyl. A roller is applied to the tape, causing it to adhere to the vinyl. The transfer tape and the weeded vinyl is pulled off the release liner, and applied to a substrate, such as a sheet of aluminium. This results in an aluminium sign with vinyl figures.